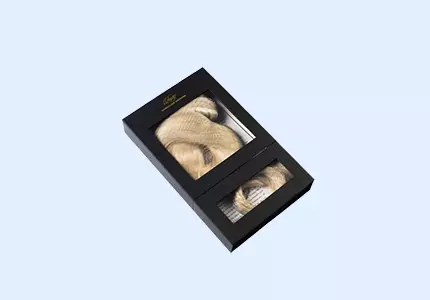

Hair Extension Packaging Wholesale

Wholesale hair extension packaging solutions with exceptional value and quality from Eco Packaging Box. We supply bulk packaging to businesses of all sizes with competitive factory-direct pricing. Our wholesale program offers various packaging styles including custom boxes, foldable designs, luxury options, and standard packaging. Volume discounts available with flexible minimum order quantities. Perfect for distributors, manufacturers, salons, and retailers needing consistent packaging supply. All wholesale orders maintain premium quality standards with customization capabilities. Choose from existing designs or create fully custom packaging. Fast production times ensure inventory availability when you need it. Dedicated account management for wholesale clients. Reduce per-unit costs while maintaining brand consistency across your product line. Partner with us for reliable, affordable packaging solutions.

Material and Paper Stock Options for Hair Extension Packaging Wholesale

SPECIFICATION

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 8-10 Business Days , Rush |

Thickness of Packaging Material

| Thickness of Packaging Material | GSM Weight |

| 13 point Pulp | 200 gsm |

| 14 point Uncoated | 270 gsm |

| 16 point C2S / Solid Bleached Sulfate (SBS)* | 350 gsm |

| 18 point C2S | 400 gsm |

| 24 point Uncoated | 405 gsm |

| 24 point C2S / Solid Bleached Sulfate (SBS)* | 460 gsm |

| 40 point Cotton | 600 gsm |

Paper Stock

Duplex Chipboard

|

Grey Chipboard Cardboard

|

Textured

|

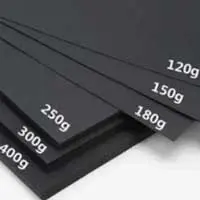

Black Kraft

|

Holographic

|

Natural Brown Kraft

|

Metallic Paper

|

SBS C2S

|

White Kraft

|

Our Finishing Option

Foil Stamping

|

Gloss

|

Spot UV

|

Matte

|

Holographic Foiling

|

Embossing

|

Debossing

|

Soft Touch Lamination

|

Unlock Endless Custom Boxes & Packaging Ideas

Chat live with our packaging pros for a free consultation and get an instant price quote now!

Hair Extension Packaging Wholesale

Let’s talk about the packaging math that keeps you up at night. You’re ordering packaging in smaller batches, paying premium prices, dealing with frequent reorders, and watching those per-unit costs eat into margins you can’t afford to lose. Meanwhile, your business is growing, inventory is turning faster, and you need packaging solutions that scale with you instead of holding you back. At Eco Packaging Box, our hair extension packaging wholesale program isn’t just about buying in bulk—it’s about fundamentally changing your packaging economics, streamlining operations, and building a supply chain partnership that actually supports growth instead of creating headaches.

The True Cost of Not Buying Wholesale

Small-batch ordering seems safe and flexible, but the hidden costs add up faster than most business owners realize until they actually do the math.

Price Per Unit vs Total Cost of Ownership

Here’s the calculation most people miss: you’re not just paying for boxes—you’re paying for multiple shipments, repeated order processing, inconsistent pricing, rush fees when you run low, and the opportunity cost of time spent managing constant reorders. Let’s say you’re ordering 500 boxes monthly at $2.50 each. That’s $1,250 per month or $15,000 annually just for boxes. Switch to wholesale ordering—say 5,000 boxes quarterly at $1.50 each—and you’re paying $7,500 total, half your annual packaging cost for identical products. That $7,500 savings goes directly to your bottom line, or gets reinvested in better hair quality, marketing, or expansion. As part of our cosmetic boxes wholesale program, we’ve watched businesses redirect those savings into growth initiatives that wouldn’t have been possible with small-batch pricing eating up profits.

The Compounding Advantage of Volume Pricing

Wholesale pricing improves as order volumes increase—it’s tiered, meaning the more you buy, the better your per-unit price gets. Order 2,000 boxes and you might pay $2.00 each. Order 5,000 and that drops to $1.50. Order 10,000 and suddenly you’re at $1.20. This creates compounding advantages as your business grows. Your packaging costs don’t scale linearly with growth—they actually decrease as a percentage of revenue, improving margins exactly when growth demands capital for inventory, marketing, and operations. Smart businesses leverage this by forecasting packaging needs six to twelve months out and placing larger orders that lock in better pricing while funding is available.

Building Reliable Supply Chains That Support Growth

Running out of packaging stops sales as effectively as running out of product. Wholesale programs create supply chain stability that small-batch ordering simply can’t match.

Predictable Inventory Management

Wholesale ordering transforms packaging from constant fire drill into predictable, manageable inventory. Instead of monitoring stock levels weekly and placing emergency orders when you’re down to the last 50 boxes, you order quarterly or semi-annually based on sales projections. Our hair extension packaging wholesale clients typically maintain three to six months of packaging inventory, giving them buffer against demand spikes, shipping delays, or production issues. This predictability extends to cash flow planning—you know your packaging costs for the quarter, can budget accordingly, and aren’t hit with unexpected expenses when you need to reorder sooner than planned.

Consistent Quality Across Production Runs

One of wholesale’s underappreciated advantages is consistency. When you order 5,000 boxes at once, they’re all from the same production run—identical color matching, identical material specs, identical print quality. Your brand looks cohesive whether someone buys in January or June. Small-batch ordering from various suppliers or even the same supplier across multiple production runs introduces variation. One batch has slightly different purple, the next has subtly different finish—individually minor, collectively problematic for brand consistency. Wholesale eliminates that variability. We store your exact specifications, color formulas, and design files, ensuring perfect consistency not just within orders but across multiple wholesale orders over years.

Strategic Flexibility Within Wholesale Programs

Wholesale doesn’t mean you’re locked into one product type forever. Smart wholesale programs offer flexibility that supports evolving business needs.

Mix and Match Product Options

You don’t have to order 10,000 identical boxes. Wholesale programs accommodate variety within single orders—maybe you need 4,000 of your standard black boxes, 3,000 luxury rigid boxes for your premium line, 2,000 seasonal boxes for holiday promotions, and 1,000 window boxes for new products launching next quarter. Ordering all 10,000 pieces together gets you wholesale pricing across all variations while giving you the product mix your business actually needs. This approach is perfect for brands with multiple product tiers or seasonal collections where different packaging serves different purposes but you want economies of scale across your entire packaging program.

Phased Delivery and Warehousing Solutions

The biggest objection to wholesale is storage—”I don’t have space for 10,000 boxes.” We solve this with flexible delivery schedules. Order 10,000 boxes, take delivery of 2,500 now, and we store the remaining 7,500, shipping additional quantities as you need them. You get wholesale pricing without warehouse challenges. Some clients use scheduled releases—shipments arrive monthly or quarterly automatically based on projected consumption. Others opt for on-demand releases where they request shipments as inventory depletes. These arrangements require planning and minimum order commitments, but they remove the storage barrier that prevents many businesses from accessing wholesale pricing.

Quality Assurance at Scale

Larger volumes don’t mean lower quality—actually, wholesale production often enables better quality control through dedicated production runs and specialized attention.

Dedicated Production Runs

When you order wholesale quantities, you’re not getting boxes cobbled together from whatever’s running that day. You get dedicated production runs where machinery is set up specifically for your job, color calibrations are done precisely for your brand standards, and quality control focuses exclusively on your order. This dedicated attention typically results in better quality and tighter tolerances than small batches rushed between other jobs. Production teams can dial in settings, make adjustments, and ensure every box meets specifications without the time pressure of constantly switching between different client orders.

Statistical Quality Control

At wholesale volumes, we implement statistical quality control—systematic sampling and testing throughout production runs. We’re checking color consistency, material thickness, print registration, structural integrity, and finish quality at multiple points during production. Any deviation from specifications gets caught and corrected before thousands of units are affected. Small batches often get visual inspection but not the rigorous statistical sampling that wholesale volumes justify. The result is actually higher confidence in quality consistency across wholesale orders than across multiple small batches from various production runs.

Partnership Approach to Wholesale Relationships

Wholesale isn’t transactional—it’s a partnership where your success directly impacts our success, creating aligned incentives.

Dedicated Account Management

Wholesale clients get assigned account managers who become genuine partners in your business. They learn your products, understand your market positioning, know your seasonal patterns, and proactively suggest improvements or optimizations. Need to launch a limited edition collection? Your account manager helps develop packaging concepts. Rebranding? They coordinate the transition from old to new packaging, managing timing so you don’t get stuck with obsolete inventory. Experiencing unexpected growth? They help you scale packaging supply without disruption. This relationship continuity creates efficiency—you’re not explaining your business to different customer service reps with each order.

Proactive Planning and Forecasting Support

Good wholesale partners don’t just fill orders—they help you plan them. Based on your historical ordering patterns and business goals, account managers provide forecasting assistance. “Based on last year’s Q4 spike, you’ll probably need to order by September to have inventory for holiday season.” These insights prevent stockouts during critical sales periods and help you time wholesale orders to optimize cash flow—ordering when you have capital available rather than when you’re desperate and possibly cash-constrained.

Customization Options at Wholesale Volumes

Wholesale quantities don’t limit customization—they actually enable options that aren’t economical for small batches.

Complex Finishing Techniques

Some premium finishing techniques have setup costs that make them prohibitively expensive for small orders but perfectly viable at wholesale volumes. Embossing requires creating dies—expensive one-time cost amortized across units. For 500 boxes, that die cost adds $2+ per box. For 5,000 boxes, it’s $0.20 per box—suddenly affordable. Multi-color foil stamping, complex die-cutting, specialty coatings—all become economically feasible at wholesale volumes. This means your packaging can be more distinctive and premium at wholesale volumes than you could afford with small-batch ordering.

Prototyping and Iteration

Wholesale commitments justify investment in prototyping and refinement before full production. We create physical samples, make revisions based on your feedback, iterate until the design is perfect, then produce the full wholesale run. Small orders often skip this step due to time and cost constraints—you describe what you want, hope it turns out right, and deal with it if there are issues. Wholesale quantities justify the upfront investment in getting everything exactly right before committing to thousands of units.

Scaling Wholesale as Your Business Grows

Wholesale programs should grow with you, not create rigid commitments that become constraints.

Flexible Minimum Order Quantities

Our wholesale minimums are accessible for growing businesses—you don’t need to order 50,000 units to access wholesale pricing. Starting minimums might be 2,000-3,000 pieces, achievable for businesses doing even moderate volume. As you grow and order larger quantities, pricing continues improving through tiered structures. This graduated approach means wholesale becomes more advantageous as you scale rather than being all-or-nothing proposition accessible only to established large operations.

Seasonal and Promotional Flexibility

Wholesale programs accommodate business realities like seasonal fluctuations and promotional needs. Maybe you need larger quantities in Q4 for holiday sales but reduced inventory in slower periods. Wholesale agreements can reflect these patterns rather than forcing uniform quarterly orders that don’t match your business rhythm. Special promotional packaging for launches or events can be incorporated into wholesale programs, getting you better pricing than one-off special orders while maintaining the flexibility to test new concepts.

Risk Mitigation in Wholesale Commitments

The biggest wholesale hesitation is commitment risk—what if demand changes, products evolve, or you’re stuck with obsolete packaging?

Design Longevity and Evergreen Packaging

Smart wholesale strategies use packaging designs that remain relevant across product cycles. Core branding elements stay consistent even as specific products change. This “evergreen” approach means wholesale packaging ordered today works for products launched six months from now. Many successful brands use standardized packaging across product lines—same boxes, different interior configurations or labels for different products. This standardization maximizes wholesale efficiency while minimizing obsolescence risk.

Phased Commitments for New Products

For new products or untested markets, we offer phased wholesale approaches. Commit to smaller wholesale quantities initially—say 2,000 pieces—with pricing that approaches full wholesale levels. If the product succeeds, you transition to larger wholesale orders with better pricing. If it doesn’t, you haven’t overcommitted to packaging you’ll never use. This structure balances wholesale advantages with prudent risk management for businesses testing new concepts.

Similar Products: Check out our Hair Extension Boxes Wholesale for bulk box ordering with exceptional volume pricing, explore Custom Hair Extension Boxes available in wholesale quantities with complete design customization, and discover Foldable Hair Extension Boxes at wholesale pricing that combines space-efficiency with volume discounts.

Related Products

Custom Hair Extension Boxes

Learn more....

Luxury Hair Extension Boxes

Learn more....

Hair Extension Boxes Wholesale

Learn more....

Custom Printed Hair Extension Boxes

Learn more....

Hair Extension Packaging Boxes

Learn more....

Custom Cardboard Extension Boxes

Learn more....

Window Hair Extension Boxes

Learn more....

Custom Matte Black Hair Extension boxes

Learn more....